How to Make Bio-Materials — and Create the Future from Your Kitchen

Innovation

Learn how to turn algae into natural plastic, and get a life lesson in pursuing what you're passionate about, from Nike designer Rikke Bonde.

“Hands On” is a series where you’ll learn tactile techniques from expert innovators.

Ever found yourself seeking comfort in banana bread recipes, or fighting off boredom by experimenting with a sourdough starter? Well, Nike materials designer Rikke Bonde has a kitchen tutorial for you that's … a little different.

"When the pandemic started, I saw it as a great opportunity to experiment at home", she says. Working remotely, Rikke decided to kick-start a side project that had been on her mind—she set up a simple laboratory where she could research, test and develop dozens of recipes for bio-materials: durable plastic- or rubber-like substances made from natural ingredients. "I set up my own rules, like only using items that you have [around the house]", she says of her sustainability-minded approach.

"I think [bio-materials are] the future", Rikke says. "We have too much [stuff] lying around, and we need to figure out how to reuse it or give it a new purpose. How do we look at the materials that have the least impact on the planet? How can we merge these materials together to make them stronger, or better, or with a new aesthetic?"

Part designer, part scientist, part chef: Rikke's day job at Nike is about continuously innovating the toolkit of materials available to footwear designers. With her bio-materials side project, though, she's combining her innate knack for problem-solving with chemical reactions and vegan cooking techniques.

To start exploring the answers to these questions, look no further than your own kitchen. That's where Rikke is finding and using items like milk, gelatin, algae and aquafaba (the water that chickpeas have been cooked in, sometimes used as a vegan substitute for egg whites) to invent new materials—and bringing them to life with natural dyes made from flowers, beetroot, kale and turmeric, to name a few.

For Rikke, small wins can be highly satisfying. Her continual trials, errors, tweaks and adjustments have led to countless iterations—but the thrill of discovery never fades. "It's kind of magical because the process is so simple", she says. "You start off with something, and then it ends up being something else".

Watch the video at the top to hear the story behind Rikke's home bio-lab, and learn how to make your own bio-plastic using agar (a food thickener derived from algae). Below, Rikke shares creativity tips, a curation of past experiments and a step-by-step recipe to try at home.

The magic of Rikke's materials is that each substance is totally unique, but they're all created from only a handful of bases (agar, gelatin, casein or starch) and additions (natural dyes and food wastes). AGAR: (1) coffee grounds, (2) carrot juice/eggshells/cork, (3) beetroot dye/onion peel dye, (4) food colouring/eggshells, (5) eggshells. AGAR FOAM: (6) mushroom dye, (7) mushroom dye. GELATIN: (8) blue spirulina, (9) beetroot dye/food colouring, (10) red cabbage dye, (11) beetroot dye, (12) flower dye/turmeric. GELATIN FOAM: (13) flower dye/spirulina, (14) red cabbage/turmeric. CASEIN: (15) spirulina/onion peel dye, (16) spirulina/food colouring, (17) blue spirulina. CORNSTARCH: (18) chilli flakes, (19) turmeric, (20) turmeric. POTATO STARCH: (21) experiment waste, (22) lavender.

Be Fearless (and Other Tips From Rikke)

Tip 1: There's no such thing as a bad experiment

"I failed so many times", Rikke says of her bio-material recipes. "But it made me hungry to do a second version. And now I'm working on a third version. It's just a learning curve".

Playing with ingredient amounts and temperature levels has resulted in new ideas and outcomes (some shown above), which Rikke presented to her team, "like a little museum, or a little peek into what is the future", she says.

Rikke's mix of inquisitiveness and tenacity—not quitting, even when things don't turn out the way she anticipated—has been key to her project's progress. "I think I was just fearless", she says. "I just wanted to know, and I wanted to try it myself".

Tip 2: Only use what's easily (and naturally) available

"You need to create your own dyes, and you need to do a lot of testing", Rikke says, referencing her self-imposed restriction to only use what she had.

Her experiments helped her identify a few household go-tos—like algae, which has "a lot of good benefits … It can take the carbon from the air and suck it in, and it's biodegradable", she says. "Not only can you eat it, but you can create materials, and it also binds things together".

As for aesthetics, bright flowers can be boiled with salt to extract natural dyes. "Colour for me is eye candy. I can't live in a world without colour", says Rikke, who's already contemplating a future experiment reusing her own creations. "It would be super cool if you can use bio-material to make dye as well ..."

Tip 3: Keep exploring, keep experimenting

"As a kid, I always wanted to have my own ideas bank", Rikke says of her lifelong curiosity and creativity. She's still inspired by pushing the edges of what's possible—and never one to rest on her laurels. "It's about [saying], 'OK, this was a success. How can we take it further?'"

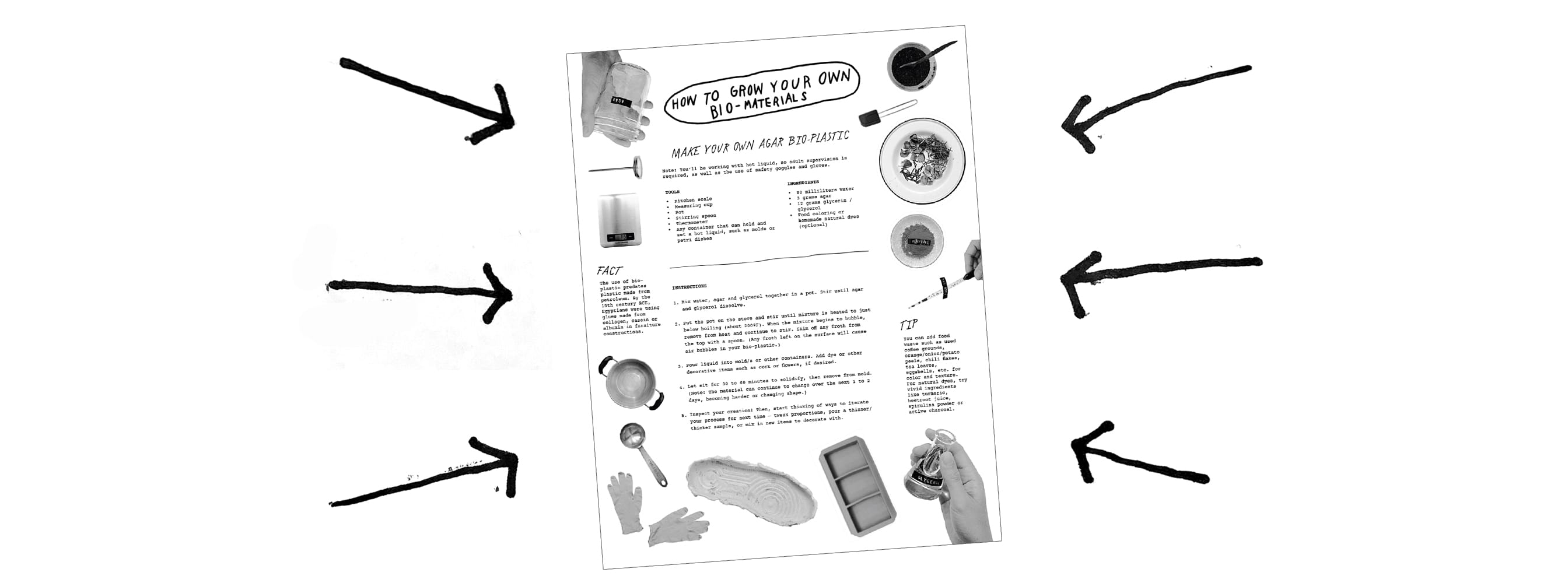

Make Your Own Agar Bio-Plastic

Here's one of Rikke's favourite bio-material recipes out of the many she's been refining! This is the same recipe demonstrated in the video above.

Note: You'll be working with hot liquid, so adult supervision is required, as well as the use of safety goggles and gloves.

Tools

- Kitchen scales

- Measuring cup

- Saucepan

- Stirring spoon

- Thermometer

- Any container that can hold and set a hot liquid, such as moulds or petri dishes

Ingredients

- 80 millilitres water

- 3 grams agar

- 12 grams glycerin/glycerol

- Food colouring or homemade natural dyes (optional)

Instructions

- Mix the water, agar and glycerol together in a saucepan. Stir until the agar and glycerol have dissolved.

- Put the saucepan on the hob and stir until mixture is heated to just below boiling (about 95ºC). When the mixture begins to bubble, remove the saucepan from the heat and continue to stir. Skim off any froth from the top with a spoon. (Any froth left on the surface will cause air bubbles in your bio-plastic.)

- Pour the liquid into mould/s or other containers. Add some dye or other decorative items such as cork or flowers, if desired.

- Let it sit for 30–60 minutes to solidify, then remove from the mould. (Note: The material can continue to change over the next 1–2 days, becoming harder or changing shape.)

- Inspect your creation! Then, start thinking of ways to iterate your process for next time—tweak proportions, pour a thinner/thicker sample or mix in new items to decorate with.

TIP: You can add food waste such as used coffee grounds, orange/onion/potato peels, chilli flakes, tea leaves, eggshells etc. for colour and texture. For natural dyes, try vivid ingredients like turmeric, beetroot juice, spirulina powder or active charcoal.

FACT: The use of bio-plastic pre-dates plastic made from petroleum. By the 15th century BCE, Egyptians were using glues made from collagen, casein or albumin in furniture construction.

For a printable version of this recipe, click below.

(Note: PDF is available in English only.)

Film: Azsa West

Words: Brinkley Fox

Reported: November 2020