Sustainable Materials and Innovation

CHOOSING OUR MATERIALS

One of our biggest steps on our journey to zero carbon and zero waste is in choosing our materials because they account for more than 70% of any product’s footprint. By reusing existing plastics, yarns, and textiles, we significantly reduce our emissions.

Nike Flyknit

Nike Flyknit is a lightweight fabric precision-engineered with an average of 60% less waste than in traditional footwear upper manufacturing. Each shoe upper made from Flyknit contains 6-7 plastic bottles.

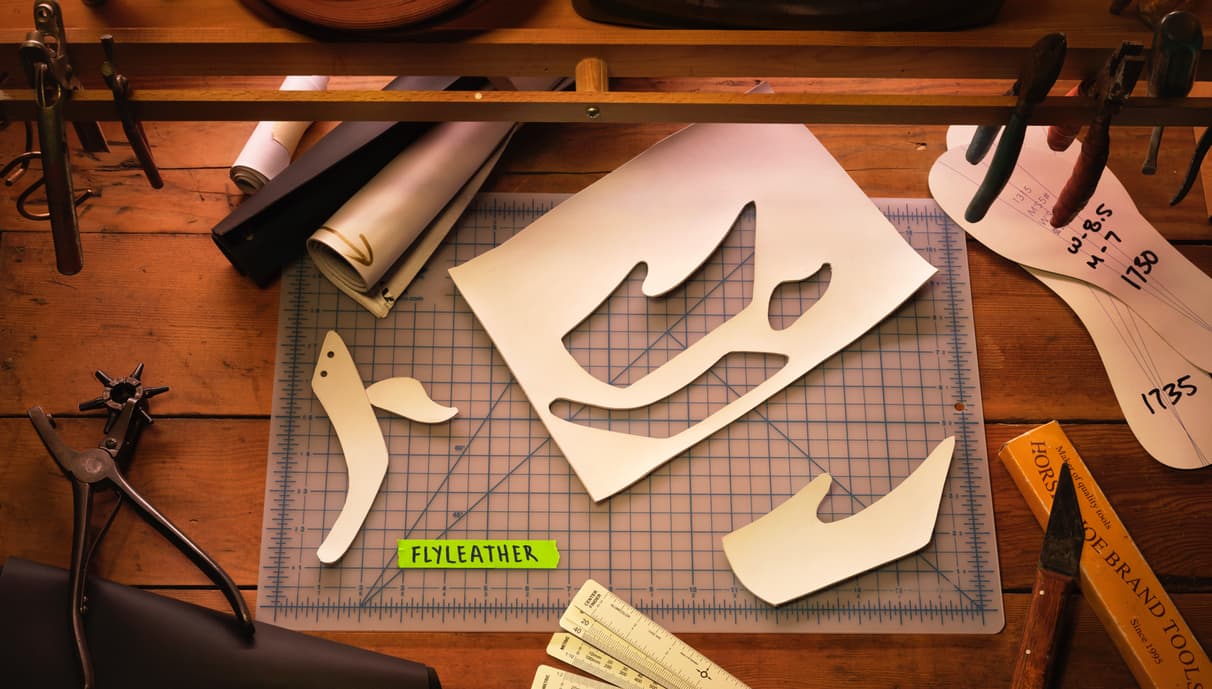

Nike Flyleather

Flyleather looks, feels and smells like natural leather, made by binding at least 50% recycled leather fibers with synthetic fibers using a water-powered process. This creates less waste and a lower impact on climate change compared to full grain leather.

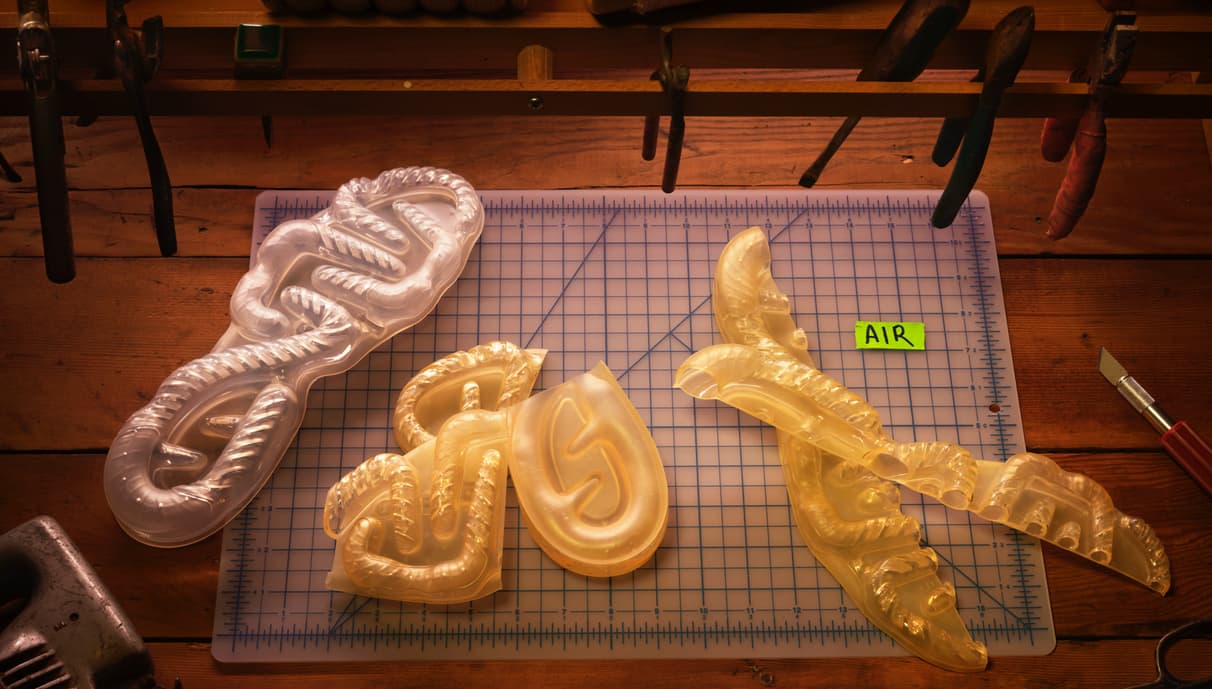

Nike Air

Since 2008, all Nike Air soles are composed of at least 50% recycled manufacturing waste. As of 2020, all of Nike’s AirMI facilities in North America are powered by 100% renewable wind energy. We reuse more than 90% of the waste from materials used for our Air soles to make new, innovative cushioning systems. Light on your feet. Light on waste.

Recycled Polyester

Our recycled polyester is made from plastic bottles which are cleaned, shredded into flakes, converted into pellets, and then spun into a high-quality yarn. In addition to reducing waste, recycled poly lowers carbon emissions by up to 30% compared to virgin poly, and diverts an average of 1 billion plastic bottles annually from landfills and waterways.

Sustainable Cotton

As of 2020, 100% of the cotton we use across our entire product line is certified organic, recycled, or Better Cotton sourced through the Better Cotton Initiative. We recycle more than 1.5 million pounds of cotton each year while caring for soil health and natural habitats, without fossil fuel-derived pesticides or synthetic fertilizers, and while respecting the rights of workers and farmers.

Recycled Nylon

Our recycled nylon is transformed from a variety of materials, like carpet and used fish nets. The nylon is cleaned, sorted, and converted into flakes, all before undergoing a chemical or mechanical recycling process. The new recycled nylon yarn reduces our carbon emissions by up to 50% compared to virgin nylon.