Nike Pegasus Premium reimagines running on air

Product news

Discover how bold innovation led to the most energy return of any Pegasus shoe.

What's the next great running innovation? It's a question that has inspired Nike since the very beginning. In 1970, Bill Bowerman used his wife's waffle iron to create the tread for some of the brand's earliest running shoes. Today, the same drive to innovate a culture of creativity has spurred a new generation of Nike footwear.

The Pegasus Premium is the company's latest innovation—designed with Nike's first sculpted visible full-length Air Zoom unit. "Air is our most responsive and durable technology for cushioning", says Paul Begyn, footwear development director of innovation.

Nike's Air technology is one of the most significant innovations to come out of Nike's innovation labs. Through decades of exploration, the Nike Sport Research Lab has helped refine game-changing Air technology. To this day, it remains a critical component in some Nike shoes, including the Nike Alphafly 3, the company's fastest ever marathon shoe.

The full-length Air unit was a long time coming. In 2016, the team first experimented with the Zoom All Out, which featured a flat Air unit that stretched from toe to heel. The innovators then prioritised improving upon the efficiency levels of the Zoom All Out.

Nike's engineers continued to look at other shoes in the line-up, namely the Vaporfly, as potential inspiration for the Air Zoom unit. "The engineers looked at the curvature of the carbon plate", says Begyn. "How it created a smooth transition for runners".

In running, energy return is crucial, as Begyn and his teammates knew quite well. The way a foot connects with the ground underneath can impact the efficiency—the better the return, the less energy the runner exerts.

Could the curved shape of the Vaporfly's carbon plate be applied to Air to aid this transition?

The breakthrough

The answer came in an unexpected way. Kevin Sze, a member of the innovation team, was at home during the COVID-19 pandemic when he had an idea.

He engineered a test using a glass bottle and cooking pot, which helped sculpt the shape of the forefoot and arch to better mimic the shape of a human foot, while applied heat helped to set the new shape of the Air unit.

"Sometimes, the simple solution is the most innovative".

Clayton Chambers

Senior director, future cushioning systems, innovation

Once Sze could show his idea to the team, he slowly began building a small quantity for prototyping. He'd done it once, but he had to prove it wasn't just a fluke. For the next step, a model was 3D printed to create a more consistent shape and to help directly control where heat would be applied. No more bottles necessary.

While the team now had proof that the Air unit could be moulded, it didn't mean it would work. The exploration phase began in the Nike Sport Research Lab, where the innovators created 35 different shoe silhouettes with the new Air Zoom unit, ranging from sleek to wildly futuristic.

"The first, unconstrained phase of exploration took place over a few days and netted us dozens of ideas across the full spectrum of mild to wild", Clayton Chambers explains. "Over the next few weeks, we cycled through the process of brainstorming, rough prototyping, trying on amongst ourselves, further refining and down-selecting as we went".

At that point, the team had whittled down the choices to just four silhouettes, which they then shared with runners. The feedback suggested that the runners could personally relate to what the team was trying to accomplish.

"That moment really galvanised the team to obsess over the refinement of the initial idea", Chambers says.

Months went by and with the same group of runners offering input at each step, the innovators' confidence and excitement grew. Something big was brewing.

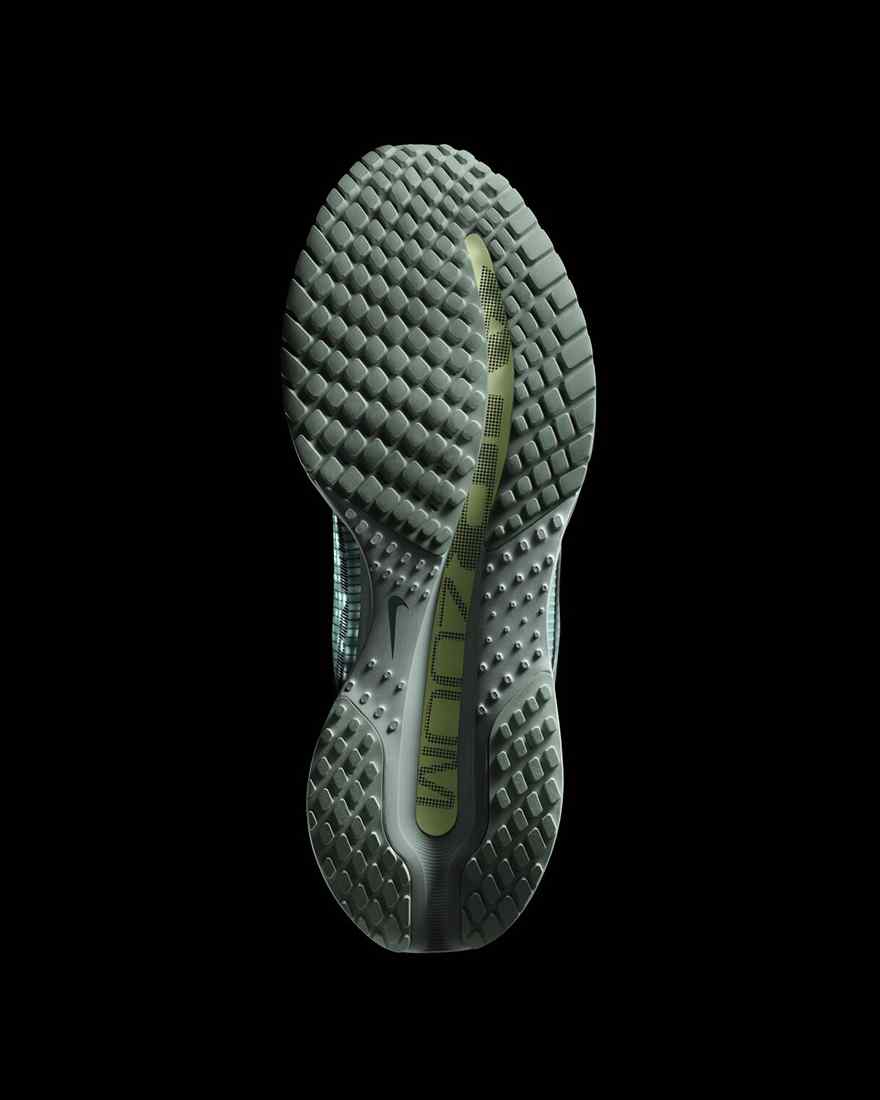

Ultimately, the team settled on an engineered mesh upper and a layered (stacked) midsole of ZoomX foam directly below the foot, a sculpted Air Zoom unit in the middle and ReactX foam in the heel.

"ReactX provides a stable but responsive base under the Air Zoom in the heel, while a full-length ZoomX foam piece above the Air Zoom contributes extra heel-to-toe energy return without a weight penalty", Chambers says.

Putting Air Zoom to the test

With the silhouette settled, testing began. Runners at Blue Ribbon Studios in Los Angeles tested the first iterations and numerous elite runners around the world were critical in refining the shoe. With each new version, the Nike team refined its vision further. The result: runners loved the responsiveness and described the Pegasus Premium as having more energy return.

Nike then brought the shoe to the Nike Sport Research Lab, where pro athletes Rai Benjamin and Jessica Hull put them to the test and praised their responsiveness.

"Whether you run on your toes more or strike heel-first,

the responsiveness is next-level".

Rai Benjamin

Olympic champion runner

"The air bubble compresses and then responds back as you toe off the ground", Hull said.

Years of innovation are finally coming to fruition, as the Pegasus Premium release date is 6 February 2025 in China and 30 January 2025 across the rest of the world. Limited quantities are available upon release. "Every innovator's dream [is] to create something that's extremely impactful", Sze says.

Now, Sze's dream is coming true. Embrace the joy of the run and experience the most energy return of any Nike Pegasus ever.